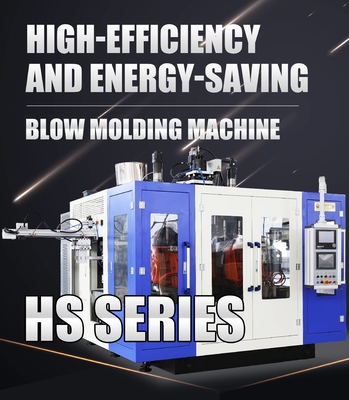

TONGDA HS series Fully Automatic Extrusion Blow Molding Machine

Product Description

This is our basic series machine.It is double station.This machine is suitable for the the daily use products.It can be equipped with several die-heads and then it is also suitable for small product.The main parts of this machine are designed and manufactured by ourself. We do the independent R&D and inspection.If you have other special requirements, we can provide customized services for you.

Technical Parameters

|

MODEL

|

Units

|

HSll-12L

|

Click for the latest discount details

Remarks: we will customize the most suitable machinery according to your requirements

|

|

Max. Product volume

|

L

|

12

|

|

|

Output of HDPE

|

kg/h

|

180 | |

|

Clamping force

|

kn

|

158

|

|

|

Screw diametre

|

mm

|

100 | |

|

Screw heating power

|

kw

|

||

|

Blow pressure

|

mpa

|

0.6

|

|

|

Size of machine

|

m

|

4.9*3.1*3.2

|

Product Details

![]()

Optional 3D Manipulator

Reduce manual sorting costs and improve productino efficiency

![]()

Bottle mouth details:The surface of the bottle mouth after the flash are perfect. Comfortable and smooth.

Handle:0ne-time molding, can achieve continuous production and meet GMP standards.

Labeling :In-Mold labeling is accurate and fast, ensuring production quality and improving production efficiency.

Quality Control:The perfect quality control system controls all aspects of prducion step by step, realizes the whole process quality control of products, and provides a strong guarantee for product quality.

Company Information

![]()

In the recent 20 years, Suzhou Tongda Machinery Co., Ltd. has been focusing on the research, development and product application of extrusion blow molding machines. The factory covers an area of more than 80 acres of land and has more than 350 employees.

Warmly welcome new and old customers to visit, to guide.

Service Network

![]()

1. Over four thousand Tongda machines have been serving customers all over the world.

FAQ

TONGDA sales consultant

1. We can provide comprehensive and professional Suggestions on equipment selection.

2. Energy consumption calculation and investment income analysis can be provided.

3. Provide tailor-made CAD drawings of workshop layout and product optimization Suggestions.

4. Extrusion plastic bottle blow molding machine has remote maintenance function

Advantages of TONGDA tech teams

1. 800 sets of customized requirements per year enable us to have rich experience across multiple industries.

2. Customize equipment models according to customer product characteristics.

3. Project responsibility system, closed-loop team cooperation between the design team and the process team, adjustment of the team, and joint creation of equipment that users are satisfied with.

4. Engineers can study abroad or participate in technical function training of the industry to master the latest information and technical trends of the industry.

5. Undertake a number of large projects, and has a group of senior technical personnel composed of the construction team, can build cable bridge, installation of a complete set of equipment.

Advantages of TONGDA after-sales team

1. Lifetime free service for the machine.

2. Quick response all day long.

3. Set up domestic service team and international service team.

4. Technicians also master the debugging and maintenance of auxiliary equipment.

5. A free 2-day training course will be provided to customers every year.

6. Special processing equipment to produce after-sales accessories to ensure rapid response to user needs.