10L HDPE Garden Use Water Pot Making Machine Flower Pot EBM Extrusion Blow Molding Machine

Product Description of our HT-12L Extrusion Blow Molding Machine

If you want to produce 5L, 10L water pot, and other flower pots, our HT-12L model extrusion blow molding machine will be suitable. It is single station, single die head, standard configuration. Not equipped with auto-deflashing unit, it is very flexible for changing molds to produce different items.

It is also suitable for starters who want to produce HDPE containers size from 5-12L.

Technical Parameters our HT-12L Extrusion Blow Molding Machine

|

MODEL

|

Units

|

HT-12L

|

Remarks: we will customize the most suitable machinery according to your requirements

|

|

Max. Product volume

|

L

|

12

|

|

|

Output of HDPE

|

kg/h

|

85 | |

|

Clamping force

|

kn

|

110

|

|

|

Screw diametre

|

mm

|

70

|

|

|

Screw heating power

|

kw

|

22 | |

|

Blow pressure

|

mpa

|

0.8

|

|

|

Size of machine

|

m

|

3.9*2.1*2.8 |

Product Details our HT-12L Extrusion Blow Molding Machine

![]()

Standard air valve, with stable function

Energy acuumulator configuration save power energy instead of using a separate oil source and motor and save space.

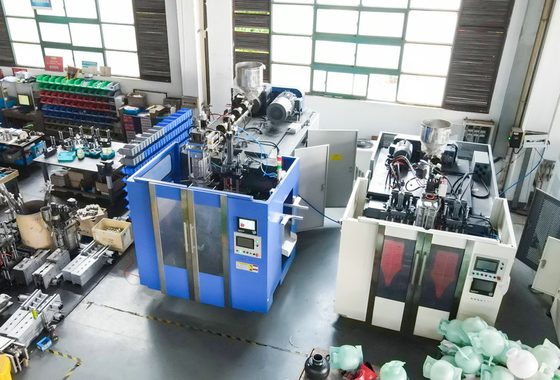

Company Information

![]()

![]()

Suzhou Tongda Machinery is a professional manufacturer of extrusion blow molding machine with over 23 years experience. And we have won the NO. 1 in China domestic extrusion blow molding field for continuously 10 years.

We have sold more than 7,000sets machines to customers from more than 120 countries and regions, annual output is 800sets/year now.

![]()

In the recent 20 years, Suzhou Tongda Machinery Co., Ltd. has been focusing on the research, development and product application of extrusion blow molding machines. The factory covers an area of more than 80 acres of land and has more than 350 employees.

Warmly welcome new and old customers to visit, to guide.

Service Network

![]()

![]()

Our Machinery has been keeping good cooperative relationship with customers since our establishing.

The satisfaction of our customers are the pursuit of every member of Tongda,The only way we service in the competitive market is to help our customers to full fill their requirement.

FAQ

TONGDA sales consultant

1. We can provide comprehensive and professional Suggestions on equipment selection.

2. Energy consumption calculation and investment income analysis can be provided.

3. Provide tailor-made CAD drawings of workshop layout and product optimization Suggestions.

4. Extrusion plastic bottle blow molding machine has remote maintenance function

Advantages of TONGDA tech teams

1. 800 sets of customized requirements per year enable us to have rich experience across multiple industries.

2. Customize equipment models according to customer product characteristics.

3. Project responsibility system, closed-loop team cooperation between the design team and the process team, adjustment of the team, and joint creation of equipment that users are satisfied with.

4. Engineers can study abroad or participate in technical function training of the industry to master the latest information and technical trends of the industry.

5. Undertake a number of large projects, and has a group of senior technical personnel composed of the construction team, can build cable bridge, installation of a complete set of equipment.

Advantages of TONGDA after-sales team

1. Lifetime free service for the machine.

2. Quick response all day long.

3. Set up domestic service team and international service team.

4. Technicians also master the debugging and maintenance of auxiliary equipment.

5. A free 2-day training course will be provided to customers every year.

6. Special processing equipment to produce after-sales accessories to ensure rapid response to user needs.